Schneideservice für Rollen und Bogen

Transverse winding – Cross-wound coil

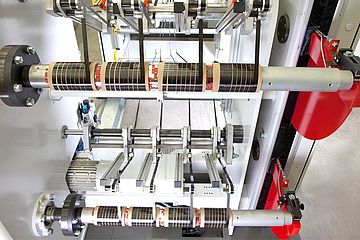

Another service we offer is the supply of carbon fibre tapes and glass fibre tapes with transverse winding. This means that the narrow tape is wound diagonally over the cardboard core, layer upon layer. This enables significantly more tape lengths to be wound per roll core, generally around ten times more on average. There is a gap between each of the tapes positioned side by side to prevent damage to the tape when unwinding.

The special thing about transverse winding is that various different options are available to choose from:

- The maximum configuration with the narrow tape on the core can be 170 mm

- We can also wind the cut tape flush with the core

- Or the core can protrude as seen in the photos

- Alternatively, the cut tape can be wound – for example, on Hafner spools

- These can have flanged wheels on the side or else have flanged wheels added

Of course, you can also opt for the best-known method, pancake winding, which involves winding the cut tape like a disc, layer upon layer, rather than cross-winding.

We will soon also be able to extend the length of your carbon and glass fibre tapes using welding techniques with ultrasound technology. This involves laying the end of one roll and the start of the new original roll on top of each other. The welding is then performed on this overlap of around 20 mm, for example.

One advantage of this is that the laying machines require less down time. It is also possible to mark the welding point so it can be recognised by sensors.